HEMPACKA Custom Logo Child Resistant Vape Cart Packaging Box

“the classic will last forever.”

Child resistant pouch is definitely a representative of personalised, quality flexible packaging, this kind of private version of the custom bag whether it is creativity, design, or bag type, material and surface decoration process are as much as possible to prove their own difference, all want to strive to become a classic presence ......

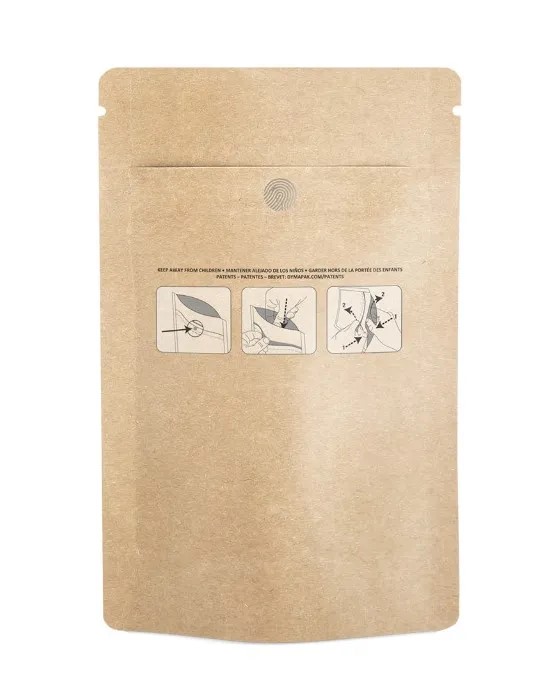

Our child resistant plastic bag are generally divided into two opening styles: "top opening" and "side opening".

Child-resistant plastic bags with zipper openings are designed to prevent children from easily accessing the contents while still allowing adults to open them with relative ease. Here are a few common methods used for child-resistant zipper openings:

- Double-Locking Zipper Description: The zipper requires the user to press two points simultaneously to unlock the zipper. This is typically done by pressing down on the zipper’s tab while pulling it open. The dual-action prevents children from easily opening the bag.

- Double-Locking Zipper How to Open: Press down on the locking points or buttons while simultaneously pulling the zipper open.

- Push-and-Turn Mechanism Description: Similar to a child-resistant cap on a bottle, this mechanism requires the user to push the zipper tab down and then twist it to open.

- Push-and-Turn Mechanism How to Open: Push the zipper tab downwards and twist it in the direction indicated, then slide it open.

- Slide-to-Unlock Zipper Description: This method involves sliding a small locking mechanism away from the zipper before you can unzip it. The lock must be disengaged before the zipper can be moved.

- Slide-to-Unlock Zipper How to Open: Slide the locking mechanism to the unlock position and then pull the zipper open.

- Description: The user needs to pinch specific areas of the zipper or the bag to disengage the lock before sliding the zipper open. This adds an extra step that is difficult for children to replicate.

- How to Open: Pinch the designated areas on the zipper or bag, then slide the zipper open.

- Description: This design requires the user to follow a specific sequence to unlock the zipper. For example, lifting a tab, pressing down, and then pulling.

- How to Open: Follow the designated sequence, usually indicated by icons or instructions on the bag.

These methods add a layer of safety to prevent children from accessing potentially dangerous items, while still being user-friendly for adults.

Each of the materials you've listed offers distinct advantages and is suited for different packaging needs. Here's an overview of these materials:

- Child resistant pouch Description: This material has a smooth, velvety texture that gives packaging a premium feel. It's often used in high-end products to enhance tactile appeal.

- Child resistant pouch Advantages:

- Provides a luxurious and sophisticated finish.

- Enhances the visual appeal with a non-glossy, muted look.

- Resistant to fingerprints and smudges.

- Child resistant pouch Applications: Luxury goods, premium consumer products, cosmetics, and electronics packaging.

- Child resistant pouch Description: A flexible film that has been aluminized and treated with a laser to create reflective, holographic effects. It offers a shiny, eye-catching appearance.

- Child resistant pouch Advantages:

- High barrier properties against moisture, oxygen, and light.

- Visually striking with holographic effects that can enhance brand visibility.

- Lightweight yet durable.

- Child resistant pouch Applications: Snack packaging, promotional packaging, and products requiring high barrier protection and visual appeal.

- Child resistant pouch Description: A durable, lightweight material with excellent barrier properties, often used to protect contents from moisture, light, and air.

- Child resistant pouch Advantages:

- Excellent barrier properties, preserving freshness and extending shelf life.

- Can be heat-sealed for airtight packaging.

- Protects against contamination and oxidation.

- Child resistant pouch Applications: Food packaging, pharmaceuticals, and products requiring airtight and protective packaging.

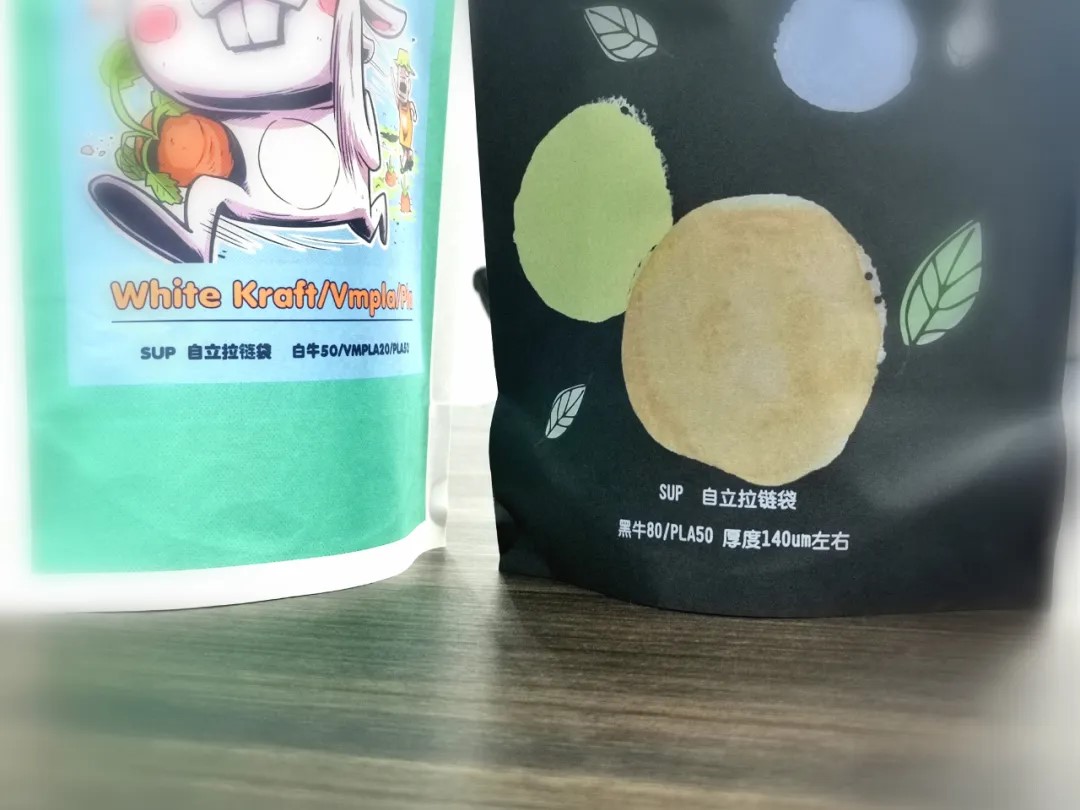

- Child resistant pouch Description: A natural, eco-friendly material made from wood pulp. It has a rustic and organic look, often used in sustainable packaging.

- Child resistant pouch Advantages:

- Eco-friendly and biodegradable.

- Provides a natural, earthy appearance.

- Strong and durable, especially when combined with other materials for added protection.

- Child resistant pouch Applications: Sustainable packaging, eco-conscious brands, organic products, and artisanal goods.

- Child resistant pouch Description: Materials specifically designed to be recycled after use, reducing environmental impact and promoting sustainability.

- Child resistant pouch Advantages:

- Reduces waste and environmental impact.

- Often made from post-consumer recycled content.

- Can be designed to maintain high performance while being eco-friendly.

- Child resistant pouch Applications: Products marketed towards environmentally conscious consumers, FMCG, and products with a strong focus on sustainability.

- Child resistant pouch Description: Materials that can break down naturally in the environment over time, reducing long-term waste. These can include plant-based plastics, starch blends, and other compostable materials.

- Child resistant pouch Advantages:

- Environmentally friendly, as they decompose naturally.

- Reduces landfill waste.

- Often perceived positively by eco-conscious consumers.

- Child resistant pouch Applications: Organic products, single-use items, and brands with a focus on sustainability and environmental responsibility.

- Product Protection: Consider the barrier properties needed to protect the contents from moisture, light, oxygen, and contamination.

- Brand Image: Choose materials that align with your brand’s values and target market. For luxury products, Soft Touch Matte might be ideal, while Kraft Paper could resonate with an eco-conscious audience.

- Environmental Impact: If sustainability is a priority, Recyclable and Biodegradable materials are excellent choices.

- Cost: Balance the material cost with the benefits it provides. Premium materials like Soft Touch Matte may be more expensive but can enhance brand perception.

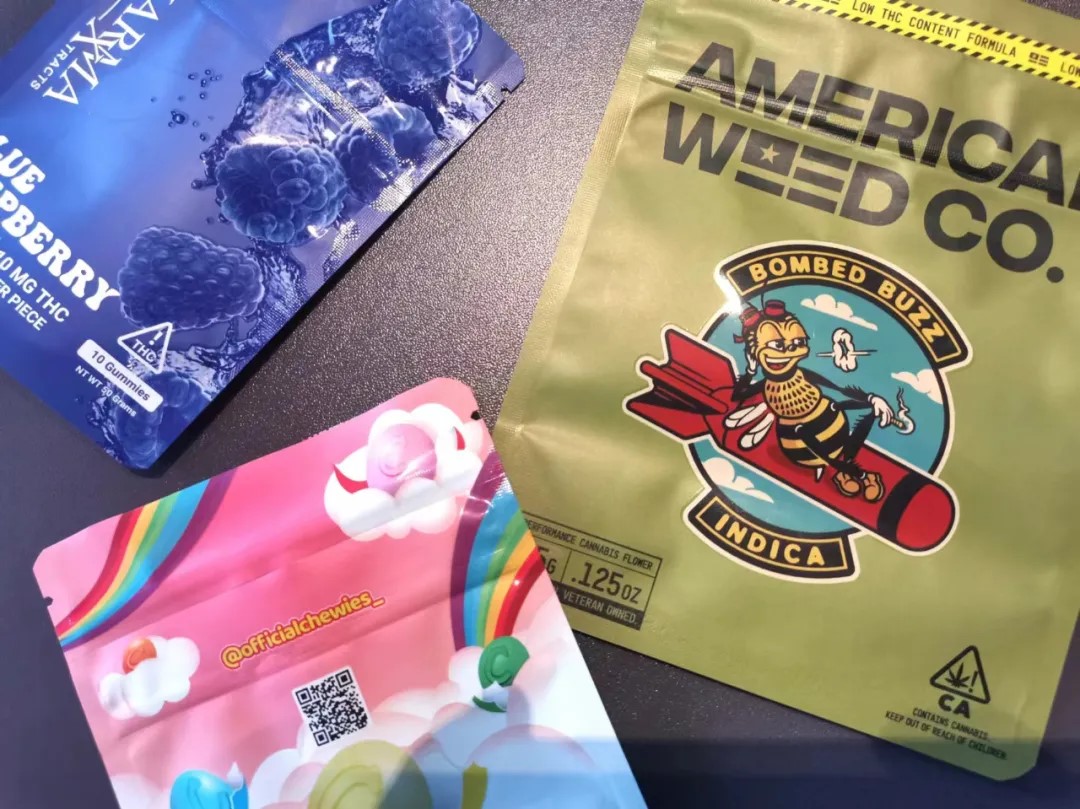

- Spot UV Description: Spot UV is a printing technique where a clear, shiny coating is applied to specific areas of a printed piece. This creates contrast by highlighting those areas with a glossy finish against a matte background.

- Spot UV Advantages:

- Adds a premium look by emphasizing specific design elements like logos, text, or patterns.

- Creates a tactile contrast between glossy and matte areas, enhancing the sensory experience.

- Increases the visual appeal with a subtle, eye-catching shine.

- Spot UV Applications: High-end packaging, business cards, luxury product packaging, and any design where certain elements need to stand out.

https://youtube.com/shorts/8WCZXW2cGB4

- Hot Stamped Description: Hot stamping involves applying a metallic or pigmented foil to a surface using heat and pressure. This creates a shiny, reflective effect that can be used to accentuate logos, borders, or text.

- Hot Stamped Advantages:

- Adds an elegant, luxurious appearance with metallic finishes like gold, silver, or holographic effects.

- Durable and long-lasting, with the ability to resist fading or scratching.

- Enhances the perceived value of the product through the use of metallic or high-gloss finishes.

- Hot Stamped Applications: Premium packaging, luxury goods, invitations, labels, and branding elements that require a touch of sophistication.

- Sandwich Printing Description: Sandwich printing involves printing between layers of material, typically used in flexible packaging. This technique allows for designs to be printed on the inside layers, protected by the outer layer, which can be transparent or semi-transparent.

- Sandwich Printing Advantages:

- Protects the printed design from scratches, wear, and environmental factors.

- Allows for intricate, multi-layered designs that create depth and visual interest.

- Enhances durability and longevity of the printed design.

- Sandwich Printing Applications: Flexible packaging for food, cosmetics, or products where the design needs to be protected from external factors, while still being visible through the packaging.

- Product Positioning: For luxury products, Spot UV and Hot Stamping can add the necessary touch of elegance. Sandwich Printing is ideal for products that require durable and protective packaging while still showcasing the design.

- Design Complexity: Spot UV is great for highlighting specific areas, while Hot Stamping is perfect for adding metallic accents. Sandwich Printing works well for complex designs that need to be protected.

- Cost Considerations: Hot Stamping can be more expensive due to the materials and process involved. Spot UV offers a balance of cost and visual impact, while Sandwich Printing is ideal for long-lasting designs that need extra protection.

- 3-Side Seal Lay Flat Pouches Description: These pouches are sealed on three sides with one open end for filling. After filling, the final side is sealed, creating a flat pouch.

- 3-Side Seal Lay Flat Pouches Advantages:

- Simple and cost-effective to produce.

- Compact and lightweight, making them easy to store and transport.

- Suitable for products that do not require a lot of space or have a short shelf life.

- 3-Side Seal Lay Flat Pouches Applications: Single-serving products, small quantities of food items, pharmaceuticals, and sample packs.

- Stand Up Pouches Description: Stand-up pouches are designed with a bottom gusset that allows them to stand upright on shelves. The "U" or "K" style refers to the shape of the gusset, which affects the pouch's stability and volume.

- Stand Up Pouches U-Style: Features a rounded bottom gusset that is folded inward.

- Stand Up Pouches K-Style: Has a "K" shaped gusset that offers a wider base and better stability.

- Stand Up Pouches Advantages:

- Stands upright on shelves, offering better visibility and branding opportunities.

- Flexible and versatile, suitable for a wide range of products.

- Can include additional features like zippers, spouts, or tear notches.

- Stand Up Pouches Applications: Snacks, dried fruits, pet food, liquid products, and bulk items.

- Pouch With Extra Pocket Description: This pouch design includes an additional pocket, which can be used for holding small accessories, utensils, or promotional items. The extra pocket is usually integrated into the front or back of the main pouch.

- Pouch With Extra Pocket Advantages:

- Provides added convenience by allowing consumers to store related items in the same package.

- Ideal for promotional purposes, where additional items can be included.

- Enhances functionality and consumer experience.

- Pouch With Extra Pocket Applications: Meal kits with condiments or utensils, cosmetic products with samples or accessories, and any product where an extra compartment adds value.

- Custom Shape Die Cut Pouches Description: These pouches are die-cut into custom shapes, tailored to the product or brand's specific needs. The unique shapes can make the product stand out on shelves and improve brand recognition.

- Custom Shape Die Cut Pouches Advantages:

- Highly customizable to reflect brand identity and product features.

- Increases shelf appeal with unique and eye-catching shapes.

- Can be designed for both aesthetic appeal and functionality.

- Custom Shape Die Cut Pouches Applications: Specialty foods, premium products, promotional items, and products where brand differentiation is key.

- Product Type: Consider the nature of your product. For liquids or bulk items, Stand Up Pouches offer the best stability. For smaller items, 3-Side Seal Lay Flat Pouches are ideal.

- Branding and Visibility: Custom Shape Die Cut Pouches** provide the most flexibility in terms of design, helping your product stand out. **Stand Up Pouches** also offer great branding space.

- Functionality: If your product requires an additional component or accessory, **Pouches With Extra Pocket** are the best option.

- Cost and Production: **3-Side Seal Lay Flat Pouches** are the most cost-effective, while custom shapes and added features like extra pockets can increase production complexity and cost.

Imagine a premium tobacco brand launching a limited-edition flavor. The packaging could be a soft-touch matte pouch with a custom shape, printed digitally in small batches. The pouch features a child-resistant zipper, with Spot UV on the brand logo and hot-stamped gold accents. The design is both visually striking and functional, meeting all regulatory standards for child safety.

By combining high-quality materials, advanced printing techniques, and child-resistant features, you can create a distinctive tobacco pouch that not only protects the product but also reinforces your brand’s commitment to safety and quality.

Hempacka will help you with all of this