HEMPACKA Smell Proof Stand Up Pouch Aluminum Foil Mylar Bag Size Large

A Mylar bag is a type of flexible packaging made from a polyester film known as BoPET (biaxially-oriented polyethylene terephthalate). Mylar is a brand name owned by DuPont Teijin Films, but the term "Mylar" is often used generically to refer to any polyester film.

These bags are commonly used for packaging a wide range of products, including food, pharmaceuticals, electronics, and more. Mylar bags are prized for their excellent barrier properties, which protect the contents from moisture, light, oxygen, and odors, helping to maintain freshness and extend shelf life.

Mylar bags come in various sizes, shapes, and styles to accommodate different products and storage needs. They can be sealed using heat sealing equipment or resealable closures like zippers, allowing for easy access and resealing.

Mylar bags are available in a wide range of specifications to cater to diverse packaging needs. Some common specifications include:

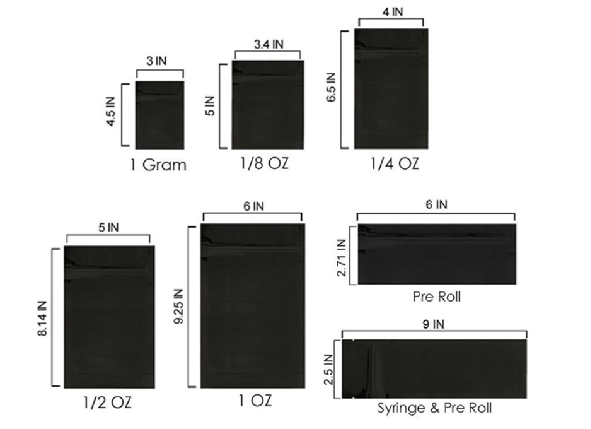

1) Size: Mylar bags come in various sizes, ranging from small pouches for single servings to large bags for bulk storage. Common sizes include 3.5 grams, 7 grams, 14 grams, 28 grams, 1 ounce, and larger sizes for industrial applications.

2) Thickness: The thickness of Mylar bags can vary depending on the intended use and the level of protection required. Common thicknesses range from 2 mil (0.002 inches) to 7 mil (0.007 inches) or even thicker for heavy-duty applications.

3) Material: Mylar bags are typically made from BoPET (biaxially-oriented polyethylene terephthalate), which is a type of polyester film. However, variations in material composition, such as metallized Mylar for added barrier properties or matte Mylar for a non-reflective finish, are also available.

4) Barrier Properties: Mylar bags may be designed with specific barrier properties to protect the contents from moisture, oxygen, light, and odors. Some bags feature multiple layers or coatings for enhanced barrier performance.

5) Closure Mechanism: Mylar bags can be sealed using various closure mechanisms, including heat seals, ziplock seals, tear notches, or adhesive seals. The choice of closure mechanism depends on factors such as convenience, resealability, and product compatibility.

6) Customization Options: Manufacturers often offer customization options for Mylar bags, allowing businesses to add branding elements, logos, labels, or printed designs to the bags. Customization can enhance product visibility, brand recognition, and consumer appeal.

7) Special Features: Some Mylar bags may include additional features such as child-resistant closures, tamper-evident seals, hanging holes, or gussets for improved storage capacity.

Overall, the specifications of Mylar bags on the market can vary widely to meet the diverse needs of different industries and applications, providing flexibility, protection, and customization options for packaging various products.

1G (95x101mm) |

3.5G (101x127+25mm) |

7G (100x150+30mm) |

14G (114x171+30mm) |

28G (150x200+40mm) |

MEDIUM EXIT BAG(8x6x2') - 203.2*152.4+50.8mm |

EXIT BAG (12x9x4'') - 304.8*228.6+101.6mm |

1/4 LB (8.26x10.6x1.57)- 209.8*269.24+39.8mm |

1/2 LB (9.45x12.5x1.57")- 240*317.5+39.8mm |

1-2 LB (14x18.5x8")- 355.6*469.9+203.2mm |

Several factors influence the price of polyester film bags, including:

1) Size and Thickness: Larger bags and thicker films require more material, which typically results in higher production costs and, consequently, higher prices.

2) Material Quality: The quality of the polyester film used in the bags can vary based on factors such as purity, strength, and barrier properties. Higher-quality materials may command a premium price due to their superior performance.

3) Barrier Properties: Polyester film bags with enhanced barrier properties, such as metallized or coated films, are often more expensive than standard films due to the additional manufacturing processes involved.

4) Customization: Customized printing, branding, labeling, or special features can increase the cost of polyester film bags. These customization options require additional time, labor, and resources during the manufacturing process.

5) Closure Mechanism: Bags with specialized closure mechanisms, such as ziplock seals or tamper-evident features, may be priced higher than standard bags due to the added complexity of the closure system.

6) Quantity and Packaging: Bulk purchasing typically results in lower unit prices, as economies of scale come into play. Additionally, the method of packaging (e.g., bulk packaging vs. individually packed bags) can affect transportation and handling costs, which may influence the overall price.

7) Market Demand and Competition: Fluctuations in market demand and competition among suppliers can impact pricing. Higher demand or limited availability of polyester film bags may lead to price increases, while increased competition may drive prices down.

8) Regulatory Compliance: Bags that comply with specific industry regulations or standards, such as food-grade certifications or child-resistant packaging requirements, may incur additional costs associated with compliance testing and certification.

9) Shipping and Logistics: Transportation costs, including shipping, handling, and storage, can contribute to the final price of polyester film bags, particularly for imported or specialty items.

Overall, the price of polyester film bags is influenced by a combination of factors related to materials, manufacturing processes, customization options, market dynamics, and logistical considerations. Understanding these factors can help businesses make informed decisions when selecting packaging solutions that balance cost-effectiveness with performance and quality.

A "3.5 Mylar" typically refers to a Mylar bag with a capacity of 3.5 grams. This size is commonly used in the cannabis industry for packaging small quantities of marijuana or cannabis products, such as flowers or concentrates. The dimensions of a 3.5 Mylar bag can vary depending on factors such as the shape of the bag (e.g., flat or stand-up pouch) and the thickness of the material used. However, it generally refers to a small-sized pouch suitable for storing and transporting a single serving or small portion of a product.

3.5 Mylar bags are generally effective for storing and preserving small quantities of various products, especially in industries like cannabis, herbs, spices, or pharmaceuticals. Here's why they are considered effective:

1) Barrier Properties: Mylar bags are made from polyester film, which provides excellent barrier properties against moisture, oxygen, light, and odors. This helps to maintain the freshness, flavor, and potency of the contents, particularly important for perishable items like herbs or cannabis.

2) Protection: The sturdy construction of Mylar bags offers protection against physical damage, such as crushing or puncturing, during handling, transportation, and storage. This ensures that the contents remain intact and undamaged until they are ready for use.

3) Portability: The compact size of 3.5 Mylar bags makes them highly portable and convenient for consumers to carry and use on the go. Whether for personal use or retail packaging, their small size allows for easy storage in pockets, purses, or backpacks.

4) Customizable: 3.5 Mylar bags can be easily customized with branding, logos, labels, or printed designs, enhancing product visibility and brand recognition. This customization option enables businesses to differentiate their products and attract consumers' attention in a competitive market.

5) Resealability: Many 3.5 Mylar bags come equipped with resealable closures, such as ziplock seals or heat seals, allowing consumers to access the contents multiple times while maintaining freshness and potency. This resealability feature enhances user convenience and prolongs the shelf life of the product.

6) Compliance: Mylar bags are often designed to comply with industry regulations and standards, such as child-resistant packaging requirements or food-grade certifications. This ensures that products packaged in 3.5 Mylar bags meet safety and quality standards for consumer use.

Overall, 3.5 Mylar bags are effective packaging solutions for small quantities of products, offering a combination of barrier protection, portability, customization options, resealability, and compliance with regulatory standards. However, their effectiveness ultimately depends on factors such as proper handling, storage conditions, and the quality of the contents being packaged.

Sealing a 3.5 Mylar bag typically involves using a heat sealer or a handheld impulse sealer. Here's a general overview of how to seal a 3.5 Mylar bag:

1) Prepare the Bag: Fill the Mylar bag with the desired quantity of product, ensuring that it does not exceed the recommended capacity of the bag.

2) Fold the Top: Fold the top of the Mylar bag over to create a flat surface for sealing. Make sure there are no wrinkles or obstructions along the sealing area to ensure a proper seal.

3) Position the Sealer: Place the folded portion of the Mylar bag between the sealing jaws of the heat sealer or impulse sealer. Position the sealing element over the folded edge, ensuring that it covers the entire width of the bag.

4) Apply Heat: Activate the heat sealer or impulse sealer to apply heat and pressure to the folded edge of the Mylar bag. The heat melts the inner layers of the bag, bonding them together to create a secure seal.

5) Hold and Cool: Hold the sealing jaws in place for a few seconds to allow the melted plastic to cool and solidify. This helps to ensure a strong and durable seal.

6) Release and Inspect: Once the sealing process is complete, release the sealing jaws and inspect the seal for any irregularities or gaps. If necessary, reseal the bag using the same process to achieve a proper seal.

7) Trim Excess Material (Optional): If desired, trim any excess material above the seal using scissors or a cutting tool to create a neat and professional finish.

8) Test the Seal: To ensure the seal is secure, gently tug on the sealed portion of the bag to check for any signs of weakness or separation. A properly sealed Mylar bag should hold its contents securely without any leakage.

By following these steps and using the appropriate sealing equipment, you can effectively seal a 3.5 Mylar bag to protect its contents and ensure freshness and integrity during storage and transportation.

The optimal thickness for 3.5 Mylar bags depends on various factors, including the type of product being packaged, desired durability, and budget considerations. Generally, 3.5 Mylar bags are available in thicknesses ranging from 3 mil (0.003 inches) to 5 mil (0.005 inches), with some variations beyond this range.

Here are some considerations for selecting the best thickness for 3.5 Mylar bags:

1) Product Protection: Thicker Mylar bags offer better protection against external factors such as moisture, oxygen, light, and odors. If you're packaging sensitive or perishable items like herbs, spices, or cannabis, a thicker bag may provide enhanced barrier properties to maintain freshness and potency.

2) Durability: Thicker Mylar bags are generally more durable and resistant to tearing, puncturing, or damage during handling, transportation, and storage. If your products require extra protection or if you anticipate rough handling, a thicker bag may be preferable to ensure product integrity.

3) Clarity and Transparency: Thinner Mylar bags may offer better clarity and transparency, allowing consumers to see the contents of the bag more clearly. If visual appeal or product visibility is important for showcasing your products, a thinner bag with higher clarity may be preferable.

4) Cost Considerations: Thicker Mylar bags typically cost more than thinner ones due to the additional material required. Consider your budget constraints and the cost-effectiveness of different thickness options when selecting the best option for your packaging needs.

5) Regulatory Compliance: Depending on the industry and product type, there may be regulatory requirements or standards governing the thickness of packaging materials. Ensure that the chosen thickness complies with relevant regulations and meets the necessary safety and quality standards.

Ultimately, the best thickness for 3.5 Mylar bags is a balance between product protection, durability, visual appeal, cost considerations, and regulatory compliance. It's advisable to conduct testing and evaluation to determine the optimal thickness based on your specific packaging requirements and the characteristics of the products being packaged.

Investing in 3.5 Mylar bags can be a strategic decision for brands looking to enhance their product packaging and overall brand image. Here are several reasons why investing in 3.5 Mylar bags can be beneficial for a brand:

1) Product Protection: 3.5 Mylar bags offer excellent protection against moisture, oxygen, light, and odors, helping to preserve the freshness, flavor, and potency of the contents. Investing in quality packaging demonstrates a commitment to delivering high-quality products to consumers.

2) Differentiation: Customized 3.5 Mylar bags with branding, logos, labels, or printed designs can help brands stand out on the retail shelf or in online marketplaces. Unique and visually appealing packaging can attract consumer attention and distinguish the brand from competitors.

3) Consumer Convenience: 3.5 Mylar bags with resealable closures, such as ziplock seals or heat seals, offer convenience and ease of use for consumers. Investing in user-friendly packaging enhances the consumer experience and encourages repeat purchases and brand loyalty.

4) Brand Recognition: Consistent branding across packaging reinforces brand recognition and strengthens brand identity. Investing in 3.5 Mylar bags with custom branding ensures that the brand is prominently displayed and recognized by consumers, building brand awareness and trust over time.

5) Regulatory Compliance: Many industries have specific packaging regulations or standards that brands must comply with. Investing in compliant 3.5 Mylar bags ensures that products meet safety, quality, and regulatory requirements, reducing the risk of non-compliance issues or recalls.

6) Marketing and Promotion: Customized 3.5 Mylar bags offer a valuable marketing opportunity for brands to communicate product information, benefits, or promotional messages directly to consumers. Investing in well-designed packaging that effectively communicates brand values and product features can help drive sales and market growth.

7) Sustainability: Eco-conscious consumers increasingly prefer sustainable packaging options. Investing in 3.5 Mylar bags made from recyclable materials or incorporating eco-friendly features demonstrates a commitment to environmental responsibility and aligns with consumer values.

8) Versatility: 3.5 Mylar bags are versatile packaging solutions suitable for a wide range of products and industries, including cannabis, herbs, spices, snacks, and pharmaceuticals. Investing in versatile packaging allows brands to adapt to changing market trends and consumer preferences.

Overall, investing in 3.5 Mylar bags can provide brands with numerous benefits, including product protection, differentiation, consumer convenience, brand recognition, regulatory compliance, marketing opportunities, sustainability, and versatility. By prioritizing quality packaging, brands can enhance their competitive advantage, strengthen customer relationships, and drive long-term success in the marketplace.

Using 3.5 Mylar bags to preserve marijuana offers several benefits that are crucial for maintaining the freshness, potency, and overall quality of the product. Here are some reasons why 3.5 Mylar bags are commonly used for this purpose:

1) Effective Barrier Protection: Mylar bags are made from polyester film, which provides excellent barrier properties against moisture, oxygen, light, and odors. This protection is essential for preserving the cannabinoid and terpene profiles of marijuana, ensuring that the product remains potent and flavorful over time.

2) Extended Shelf Life: The superior barrier properties of Mylar bags help to extend the shelf life of marijuana by minimizing exposure to external factors that can degrade its quality. Properly sealed 3.5 Mylar bags create a controlled environment that protects the product from moisture, oxidation, and light-induced degradation.

3) Prevention of Mold and Mildew: Moisture is a common culprit behind mold and mildew growth, which can compromise the safety and quality of marijuana. 3.5 Mylar bags with moisture-resistant properties help to prevent the development of mold and mildew, keeping the product safe for consumption.

4) Preservation of Aroma and Flavor: Terpenes are aromatic compounds responsible for the distinct aroma and flavor of marijuana strains. Mylar bags help to preserve the natural aroma and flavor of marijuana by minimizing exposure to external odors and contaminants.

5) Protection from UV Light: Exposure to ultraviolet (UV) light can degrade cannabinoids and cause the loss of potency in marijuana. Mylar bags offer protection against UV light, shielding the product from harmful radiation and preserving its potency and therapeutic properties.

6) Tamper-Evident Packaging: Many 3.5 Mylar bags come equipped with tamper-evident features such as heat seals or ziplock closures, providing assurance to consumers that the product has not been tampered with or compromised during storage or transportation.

7) Convenient and Portable: 3.5 Mylar bags are lightweight, compact, and portable, making them ideal for storing and transporting small quantities of marijuana. The convenient size and resealable closures of Mylar bags allow consumers to portion out the desired amount of product while keeping the rest fresh for future use.

8) Customizable Branding: Mylar bags can be customized with branding, logos, labels, or printed designs, allowing dispensaries and brands to showcase their products and differentiate themselves in the market. Customized packaging enhances brand recognition and reinforces consumer trust and loyalty.

Overall, using 3.5 Mylar bags to preserve marijuana offers a reliable and effective packaging solution that helps to maintain the freshness, potency, aroma, and flavor of the product while providing convenience, portability, and branding opportunities for businesses in the cannabis industry.

Customizing more expensive Mylar bags with child locks can be a proactive measure for brands and dispensaries operating in the cannabis industry. Here are some reasons why this customization might be beneficial:

1) Safety Compliance: Child-resistant packaging is often a legal requirement for cannabis products in many jurisdictions. Customizing Mylar bags with child locks ensures compliance with safety regulations and helps to protect children from accidental ingestion of cannabis products.

2) Responsible Branding: Brands that prioritize safety and responsible consumption can enhance their reputation and credibility by investing in child-resistant packaging. Customized Mylar bags with child locks demonstrate a commitment to consumer safety and responsible marketing practices.

3) Consumer Confidence: Child-resistant packaging instills confidence in consumers, particularly parents or caregivers, who may have concerns about the safety of cannabis products in the home. Customized Mylar bags with child locks reassure consumers that the brand prioritizes product safety and takes proactive measures to prevent accidental access by children.

4) Legal Protection: In the event of accidental ingestion or misuse of cannabis products by children, brands that use child-resistant packaging may have legal protections or defenses against liability claims. Customizing Mylar bags with child locks demonstrates a proactive approach to risk management and legal compliance.

5) Differentiation in the Market: Child-resistant packaging can be a unique selling point and a competitive advantage in the cannabis market. Brands that offer customized Mylar bags with child locks stand out from competitors and attract consumers who prioritize safety and responsible consumption practices.

6) Educational Opportunities: Customized Mylar bags with child locks provide an opportunity for brands to educate consumers about responsible cannabis use and storage practices. Packaging can include instructions or warnings about keeping cannabis products out of reach of children and how to properly use the child-resistant features.

7) Brand Loyalty: Consumers may develop loyalty to brands that prioritize their safety and well-being. Customizing Mylar bags with child locks can foster brand loyalty among consumers who appreciate the brand's commitment to safety and responsible business practices.

Overall, customizing more expensive Mylar bags with child locks offers numerous benefits, including compliance with safety regulations, responsible branding, consumer confidence, legal protection, market differentiation, educational opportunities, and brand loyalty. By investing in child-resistant packaging, brands demonstrate their commitment to safety and responsible cannabis consumption while enhancing their competitive position in the market.

We are a professional packaging supplier that focus on marijuana packaging and smoking accessory. Our team have more than 10 year experiences in selling marijuana packaging and smoking accessory. And there are over 20 different production lines in our factory, over 150 workers doing production and packaging, which guarantees a short lead time and on-time delivery. Our company is located in Foshan City, Guangdong China. We provide professional one-stop service for our cannabis planting customer and small business owner.

Over the past ten years, we have been constantly bringing forth new packaging solutions, responding to market demand, and customer feedback. Our product evolution has also witnessed our active involvement in the US/Canadian cannabis industry.

We’ve worked with over hundreds of customers mainly from the US and Canada, some are from the European countries as well. Specializing in cannabis packaging solutions and servicing numerous small businesses apart from corporate giants in the hemp industry, we understand their requirements better than most. This is what makes Hempacka the unparalleled leader in cannabis specific packaging and smoking accessories.

We’re on a mission to create earth-friendly and cost-effective cannabis packaging for the booming cannabis industry. Hempacka is the only place you’ll find sourcing & manufacturing capabilities, design resources, real people, and dependability that make brands special.

Using 3.5 Mylar bags for preserving marijuana offers numerous benefits, including effective barrier protection, extended shelf life, prevention of mold and mildew, preservation of aroma and flavor, protection from UV light, tamper-evident packaging, convenience, portability, and customizable branding options. These bags are particularly suited for storing small quantities of marijuana while maintaining freshness, potency, and quality.

Customizing more expensive Mylar bags with child locks is a proactive measure for brands and dispensaries in the cannabis industry. It ensures compliance with safety regulations, demonstrates a commitment to consumer safety and responsible consumption, instills confidence in consumers, provides legal protection, differentiates brands in the market, offers educational opportunities, and fosters brand loyalty among consumers. Child-resistant packaging enhances the overall safety and integrity of cannabis products, addressing concerns about accidental ingestion by children and promoting responsible cannabis use.

In summary, investing in 3.5 Mylar bags for preserving marijuana and customizing them with child locks offers a comprehensive solution for brands seeking to prioritize product quality, safety, and consumer satisfaction in the cannabis industry.

If you have any customized needs for cannabis packaging bags, Hempacka must be your best choice, come and contact us.